Innovative service that returns damaged restorers to operation, performing maintenance or, where appropriate, repair under a controlled workshop environment:

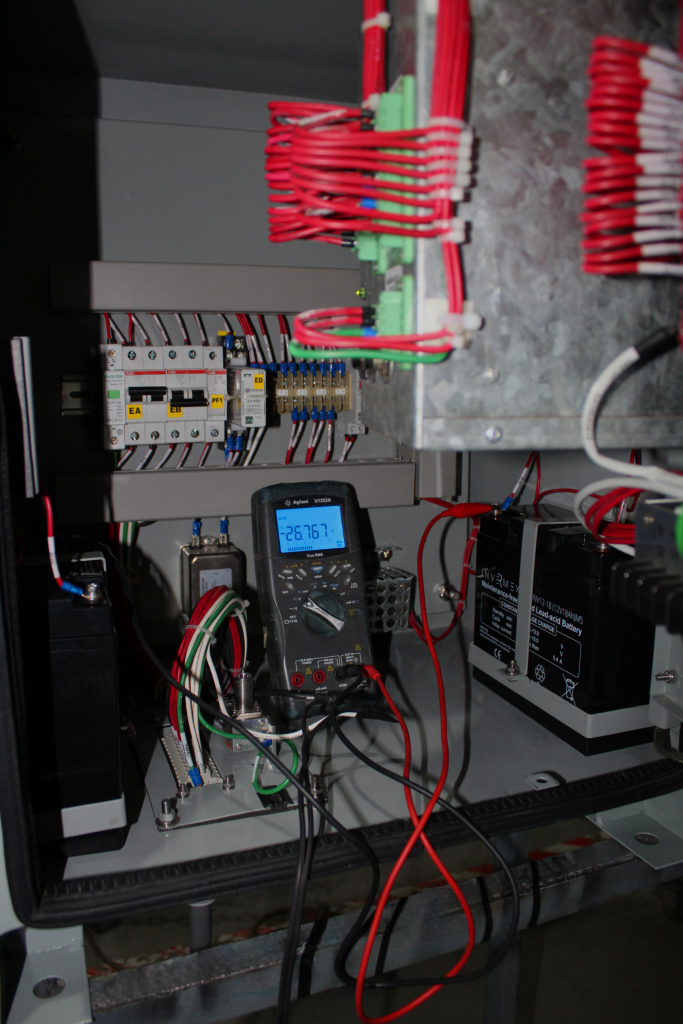

- Injection of primary voltages and currents up to 38KV and 3000A:

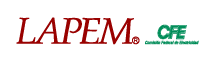

By having the possibility of injecting primary currents and voltages, a simulation of an installation environment is carried out, evaluating the performance and operation of the recloser assembly. Given the injection precision capacity, it is capable of characterizing the response of the restorer sensors. - Injection of secondary voltages and currents up to 500VAC or VDC and 30 A:

This injection is used in particular for the certification of control sensors and verification of protections. - Contact resistance:

Points with high resistance in conduction parts are a source of problems in electrical circuits, since they cause voltage drops, heat sources, power losses, etc.; This test detects those points of high resistance that can give rise to a hot spot that could cause damage to the equipment. In general, this is used in any electrical circuit in which there are sliding pressure contact points, such circuits are found in switches, disconnectors or reclosers.

- Pole disparity:

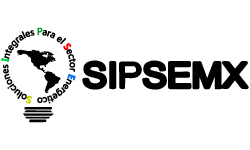

An important part is to guarantee that the poles in an event have the same or similar action. - Power factor test:

The Power Factor of an insulation is a dimensionless quantity normally expressed as a percentage, which is obtained from the result formed by the load current and the loss current that the insulation takes when applying a certain voltage, it is in itself a characteristic of its own. of insulation when subjected to electric fields. The F.P. insulation test equipment It measures load current and loss Watts, where power factor, capacitance and AC resistance can be easily calculated for a given test voltage. - Partial downloads:

They are a localized dielectric breakdown of a small portion of a dielectric insulation system subjected to stress caused by high voltage.

SIPSEMX experts in restorers, has specialized personnel, facilities and tools for the repair of any make and model of restorer.

Being the only company certified as a supplier approved by the electrical testing laboratory.

Excellent repair option, achieving greater benefit to the energy distribution company, keeping its assets in optimal operating conditions, reducing:

- Sanctions for quality of service.

- Power supply losses.

- Expense for acquisition of new assets.

- Insulation resistance:

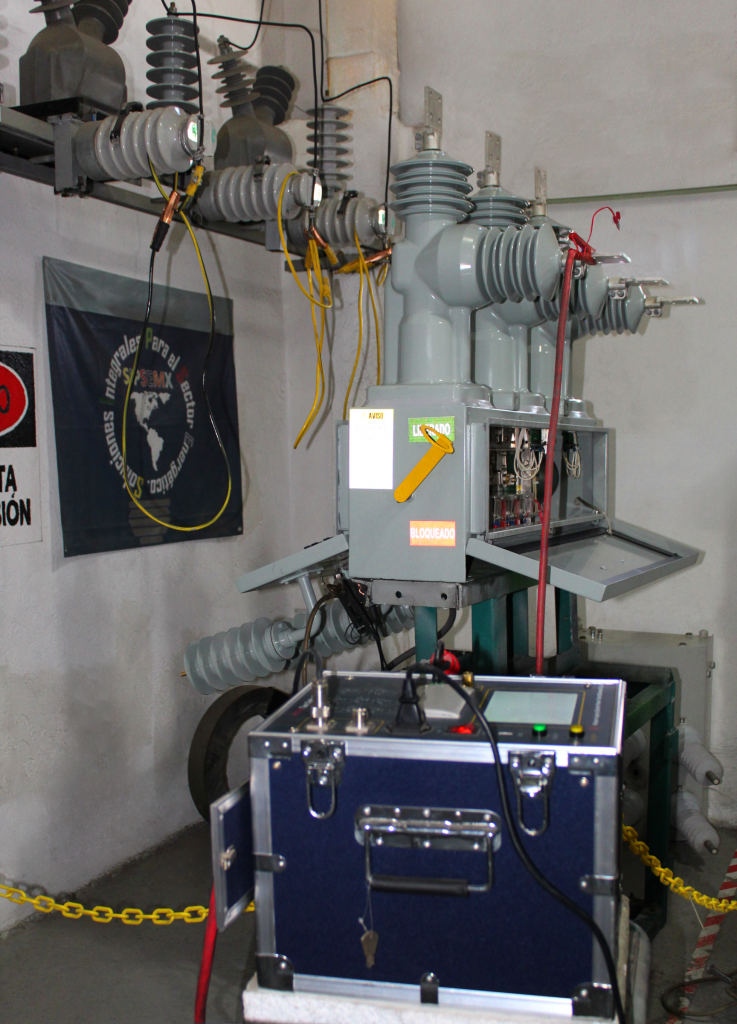

The insulation resistance measurement is in itself a potential test, therefore, it must be restricted to appropriate values that depend on the nominal operating voltage of the equipment to be tested and the conditions of its insulation. . If the test voltage is high, insulation fatigue may occur. Commonly used direct current test voltages are 500 to 5,000 Volts. - Repair and adjustment of mechanical parts:

Being a piece of equipment that has been in service, it has been subjected to both electrical and mechanical stress. Speaking of mechanical, the moving parts tend to have wear or lack of lubrication due to years of service. - Verification of operation times:

An important part of correct coordination of protections is to guarantee that the equipment in its entirety is within the acceptable operating margins. SIPSEMX has the necessary processes and tools to carry out this test.

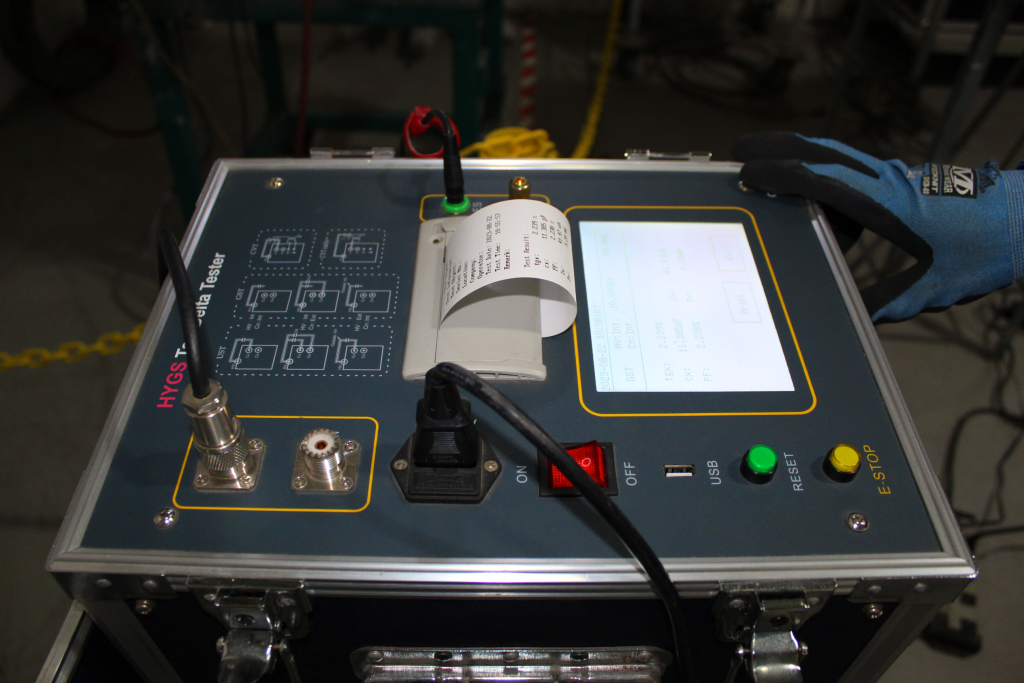

The development of the service is carried out in the SIPSEMX workshop where the restorer is disassembled into its main parts to later be evaluated in a particular way. Which are evaluated in 3 specialties:

- Electric.

- Electronic.

- Software.

Derived from the review and diagnosis, a possible repair of the damaged part or replacement is carried out.

Once the damaged parts have been repaired, the restorer is assembled again where it is evaluated in its entirety according to the current regulatory procedure.

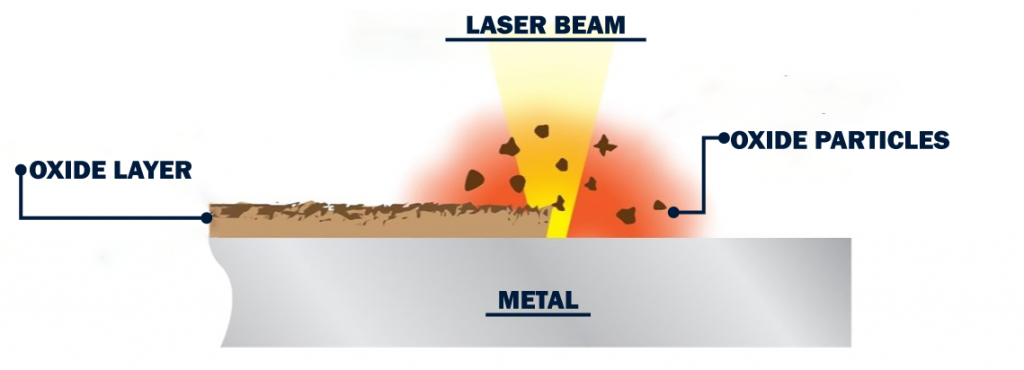

LASER CLEANING

SIPSEMX, characterized by innovative and comprehensive solutions, is the only company implementing the new laser cleaning technology applied to the repair of sectioning equipment.

Laser systems are a simple and versatile tool to eliminate corrosion, rust, scale, lubricants, paint, carbon and other contaminating elements in a clean and dry process, without deteriorating the material while preserving its composition.

Surface cleaning is a growing need in many activities, in the case of repair it is a primary situation.

Advantages:

- Non-abrasive technology minimizing wear or deterioration of the material, avoiding any change in its composition.

- Clean technology, they do not release materials, sand, dust, or metals.

- Deep cleaning, with laser cleaning it is possible to reach hard-to-reach places.

- Dry cleaning.

SERVICE TABLE

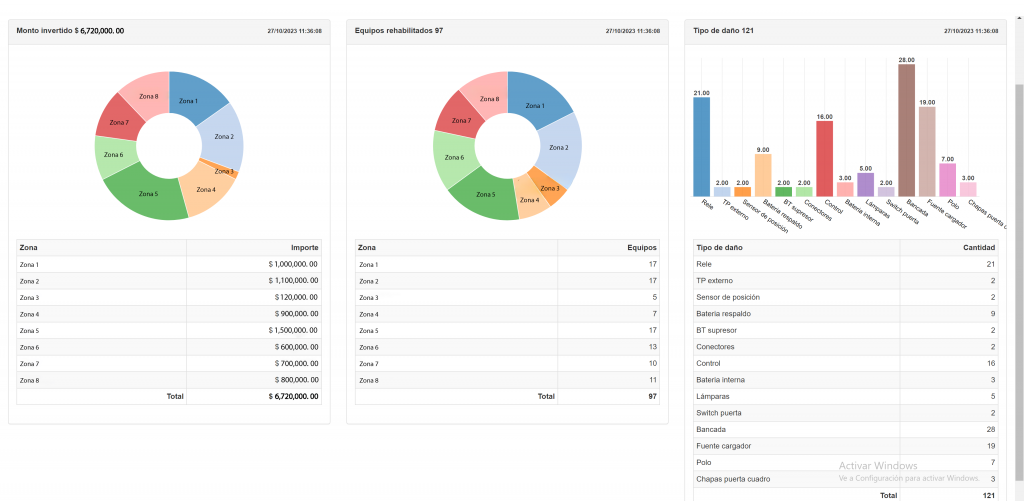

The request, follow-up and evidence are uploaded to the WEB platform available to our clients “Service Desk” accessible from the website www.sipsemx.com with personalized and password-protected access.

Where you can select the service provided by date and region.

Subsequently, with the personalized username and password, you will access the portal.

Where corrective or preventive maintenance can be requested, a service ticket is assigned agreeing on the time and date for the service. The final report displays photographic evidence, description of failures, work performed, and information on the repaired equipment.

KPIs

Generating a history of the restaurateur visited in a particular or general view of all the equipment in an area or division, representing investment, rehabilitated equipment and typical failures by brand and model. Achieving with this information the decision making in preventive maintenance.