UNIVERSAL CONTROL

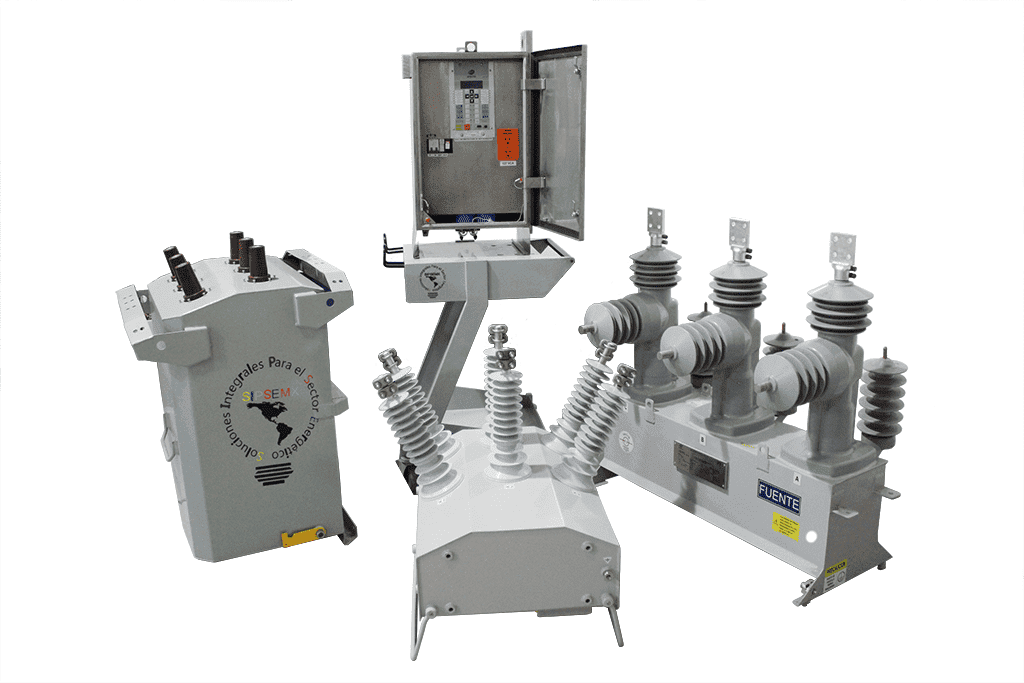

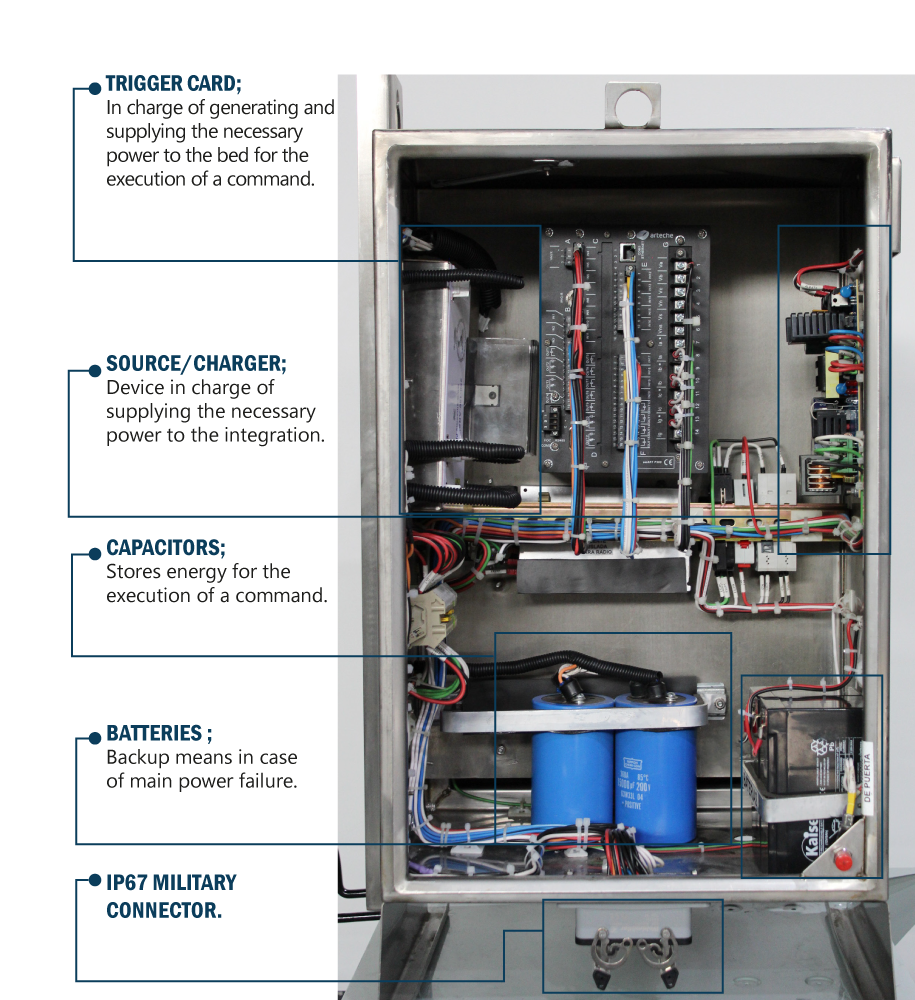

The SIPSEMX recloser control is a unique recloser control integrating the best brands on the market in various specialties and together with its own firing card, designed and manufactured at the headquarters, it is an essential device for the operation and an ideal substitute for any recloser.

VERSATILE CONTROL

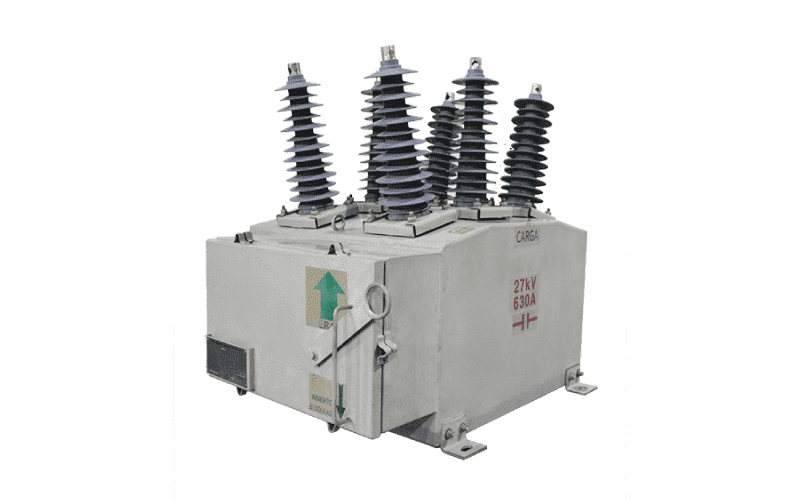

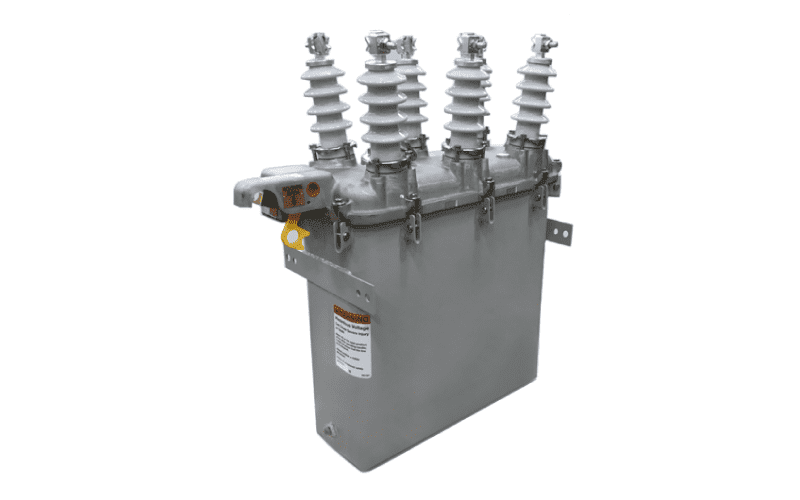

Achieving the greatest compatibility in the market in new generation reclosers and off-line reclosers. Being the same equipment applicable to one or more brands and models of reclosers, only by using the appropriate control cable for the required application, the control automatically detects the device. Unique feature in the industry.

Having one applicable control for several brands and types of primary equipment simplifies installations, reduces training and minimizes operating errors.

COST EFFECTIVE CONTROL

Equipment born out of the need for replacement controls in the repair industry, given the high mortality rate in legacy equipment controls, leaving uncontrolled primary equipment in mostly optimal condition, primary equipment with outstanding capabilities that are wasted when discarded:

The SIPSEMX universal control was designed with the purpose of reducing costs in the operation and in the acquisition of assets, aiming to return to operation legacy and off-line switching equipment to key points of the operation, bringing obsolete equipment, comparable to a state-of-the-art equipment.

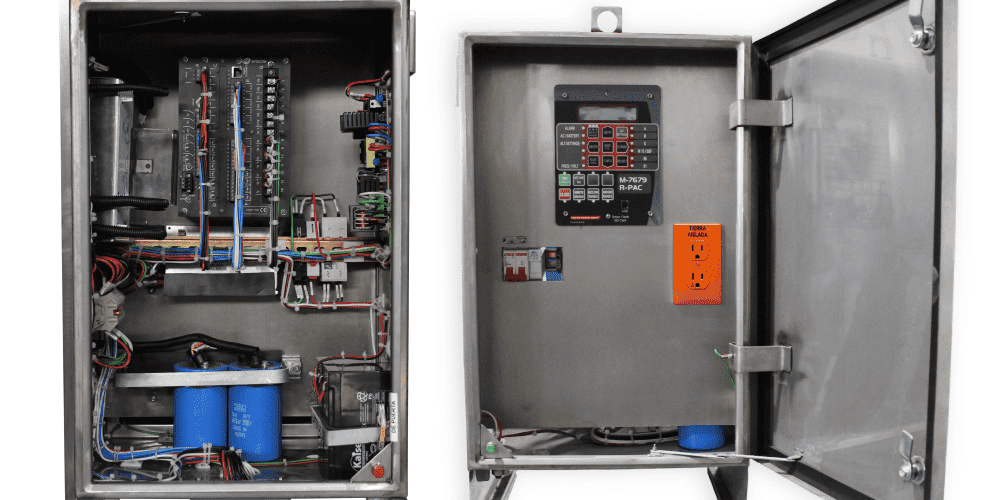

Cabinet designed for easy access and installation either on pole or substation. Made of stainless steel and double door.

CONTROL DEI

Wide variety of IEDs applicable in the integration of control, the philosophy of SIPSE Control is to adapt to our customers using an IED which has experience of use, application templates developed and implemented or simply the preferred IED to the operation.

Thus exploiting the particular advantages of each DEI at the right place in the network integration.

Protocols available:

- MODBUS®.

- DNP3.0.

- IEC 61850.

- IEC 60870-5104/101.

Entradas analógicas disponibles:

- 6 or 3 voltage inputs.

- 4 current inputs.

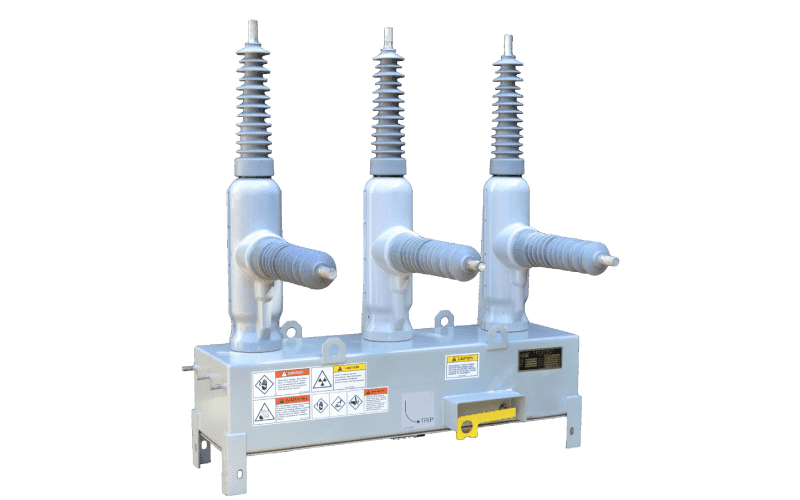

A STATE OF THE ART RESTORER?

SIPSEMX, specialists in reclosers, have developed a generic firing circuit capable of integrating most of the commercial controls to new or existing (retrofit) benches.

The main challenges of this development are:

- Speed

- Power

The two points mentioned above are of primary importance in the integration of the restorer, and are related to the mechanical and electronic composition.

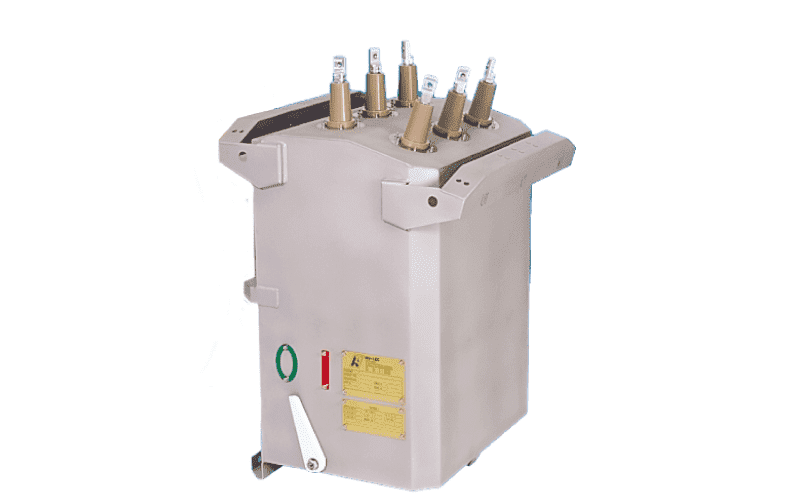

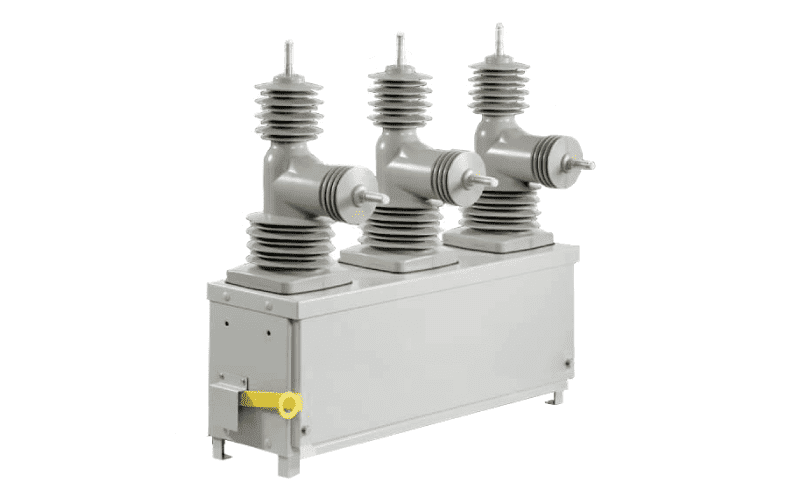

In the mechanical composition of the restorer we have the following:

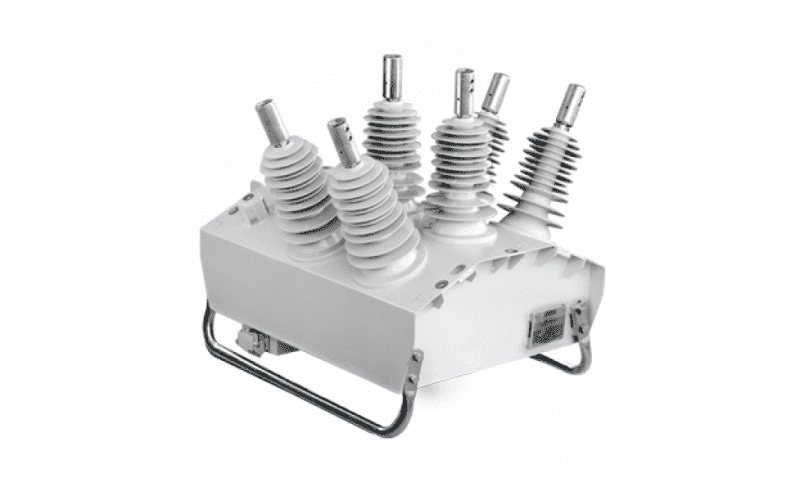

The primary equipment (bench), fast and of new generation, operate in a closing time of less than 50ms and opening time of less than 15ms.

Given this situation and in the manufacturers’ race to release the fault as soon as possible, most of them have opted for a mobile type actuator with permanent magnets.

At this point there are several advantages.

- Magnetically light: his means that the power required for their magnetization and consequently perform a movement is low and the higher this power has an impact on contact movement.

- Mechanically fast: Given its composition at the moment the actuator exerts its movement this goes inversely affecting the position of the contact reducing the time of a command.

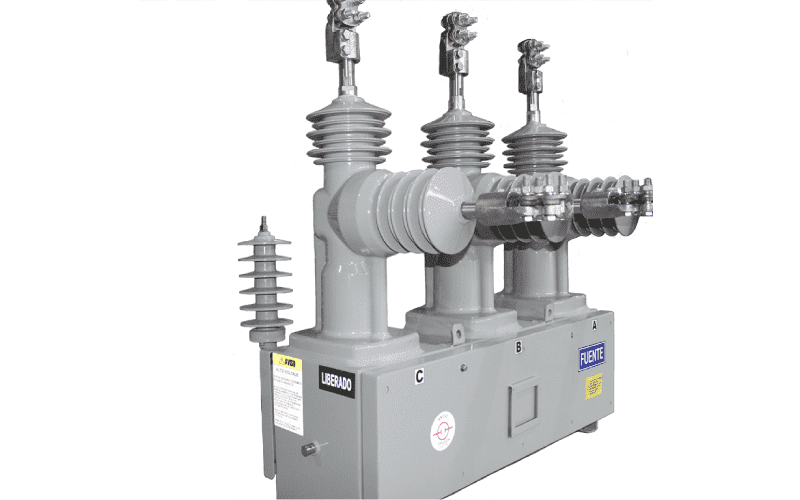

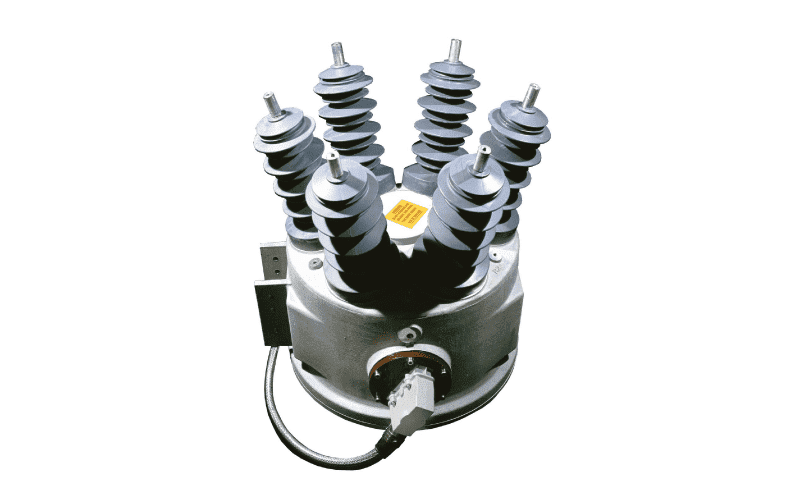

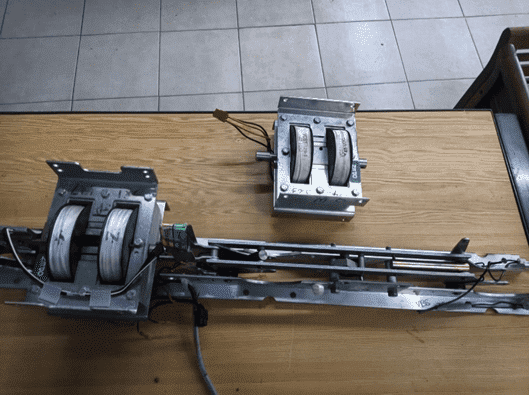

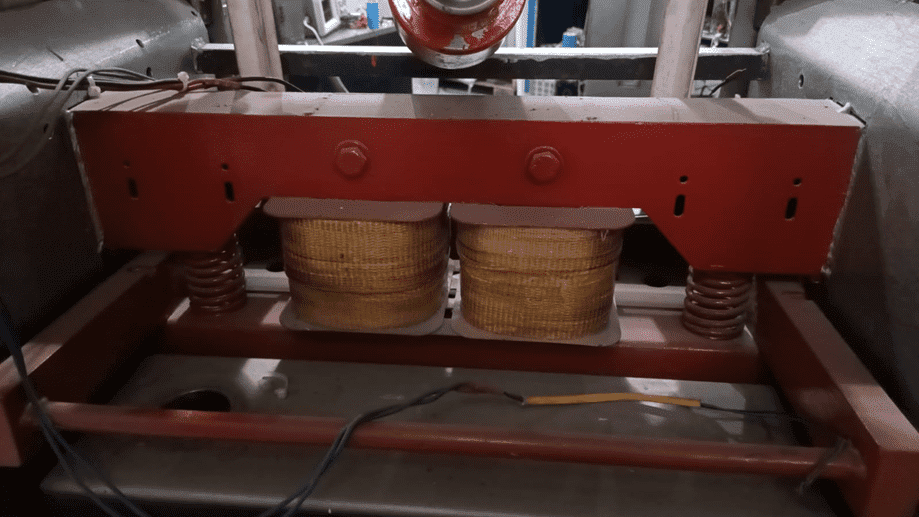

Unlike some off-line benches where the mechanism is a solenoid type actuator.

Disadvantages:

- Magnetically heavy.

Given the type of mechanism, the power required for its magnetization is large and most of this power is wasted in the magnetic field. - Mechanically slow.

Given its nature, time is sacrificed for the power to act, time is first extended by magnetizing the field, once magnetized, the mechanical part begins its operation..

Approximate opening time = 80 ms

Approximate Closing Time = 80 ms

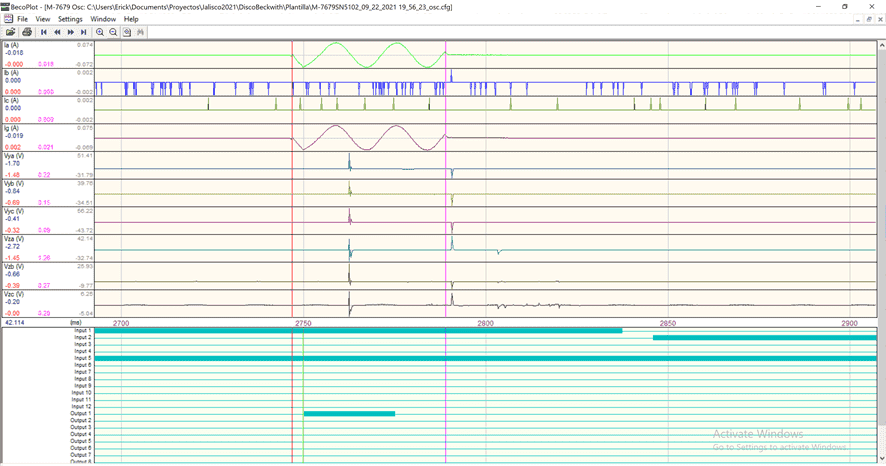

The image shows the opening of a «slow» solenoid bank in controlled fault with the SIPSEMX trip circuit, resulting in a fault release in 42 ms less than 3 cycles. Improving the time of action, limited by the mechanical part of the bench.

AT SIPSEMX WE ARE COMMITTED TO OUR CLIENTS…

The SIPSEMX control was designed for a useful life of 10 years, being modular and scalable, having the possibility of repair in all its components and being the same equipment for different reclosers, it can be relocated to a different primary equipment only using the appropriate control cable.

Having a better control and management of the network has an impact on SAIFI and SAIDI to achieve this with a lower investment, impacts on the energy supply company to be more profitable by exploiting its assets to the maximum, investing what is necessary for the functionality required in the integration of the network.